Which Concrete Admixtures Sika Supports in Your Project Needs

Our local sales and technical services teams support you throughout every phase of the construction process: from the initial consultation and project planning phase, to the detailed design phase and application on the job site and finally quality control, completion and final handover.

Engineering of concrete structures is a continuously evolving process. Invention and development of new construction methods place increasing demands on the building materials. Concrete producers face this technological challenge daily alongside other factors such as economy, ecology, raw material and energy costs and logistical complexity. In the duration of the whole construction process, time itself is an increasingly important factor.

Sika provides a wide range of concrete admixtures with innovative options for concrete mix design, whether it's for substantially reducing the water content of a mix (e.g. with Sika® ViscoCrete), using a more economical mix design or achieving sufficient early strength. Sika's concrete admixtures help you meet the challenges of modern concrete technology and the construction business.

- Wet Precast

Structural design and construction with precast concrete elements requires versatile products, from wet precast production to erection on site. Sika, a full range supplier, meets the diverse complexity of the entire precast concrete element production and construction process with solutions for all requirements, e.g. SikaRapid® for fast cycle times.

- Semi-Dry Precast

The semi-dry precast concrete industry manufactures large quantities of finished concrete products with high quality surface appearance and excellent durability. SikaPaver® products significantly improve both the manufacturing process as well as the quality of semi-dry precast concrete products. Furthermore, it is possible to reduce efflorescence or even incorporate water-repellent behavior by using SikaPaver® AE.

- Shotcrete Solutions

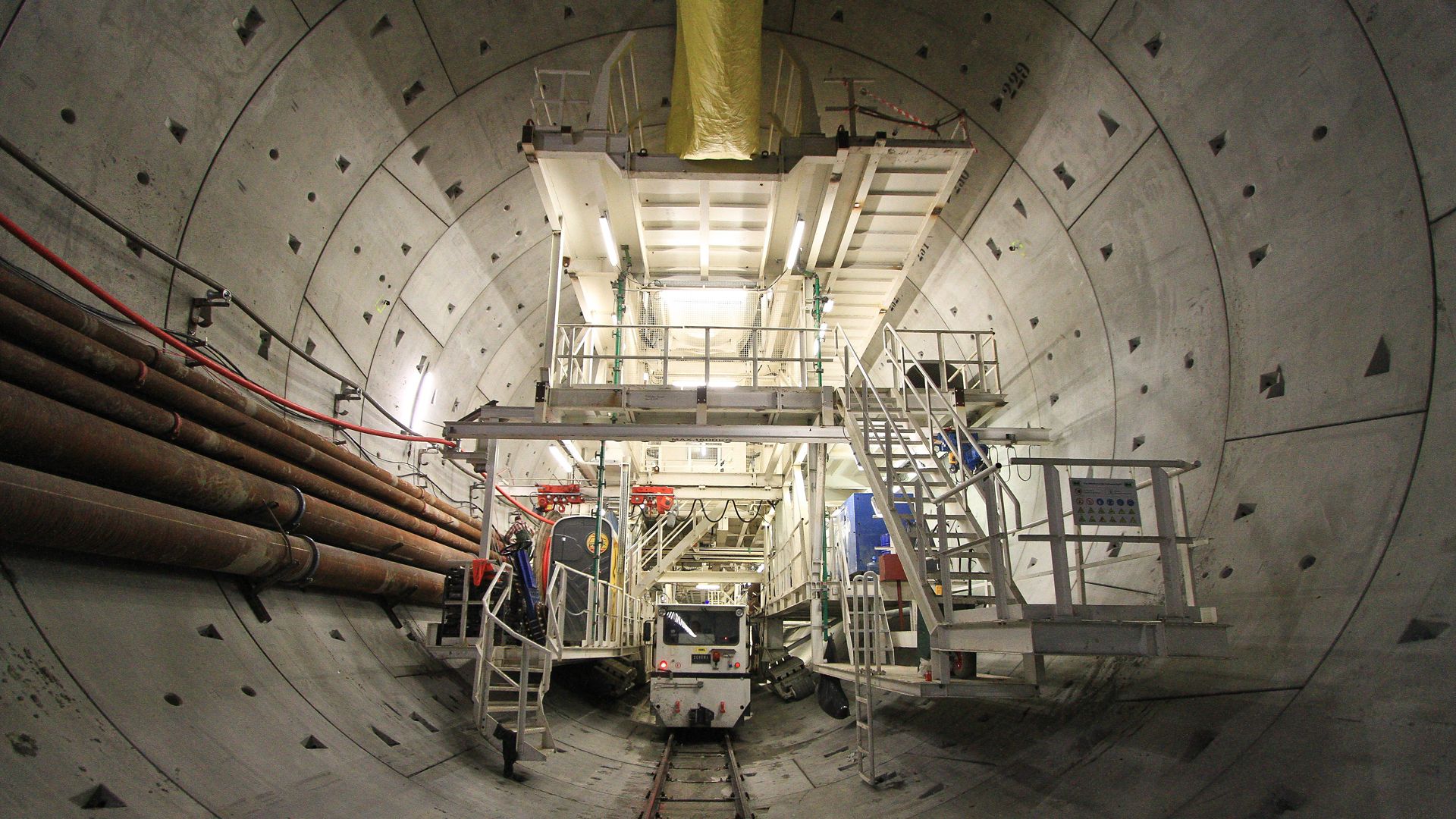

Sika is the expert in all sprayed concrete technologies, including both wet and dry spray processes. This allows us to provide the optimum solution for each type of project and application, including the development of our own Aliva sprayed concrete machines. When combined with our research, development and globalized production of specialized sprayed concrete admixtures, such as Sika® Sigunit® and Sika® ViscoCrete®, plus our years of experience in tunneling, mining and all types of major construction projects, this makes Sika the ideal partner for owners, designers and contractors on any type of sprayed concrete works.

Sika’s professional products have been approved on the biggest job sites in the world. Besides the direct sales to contractors and concrete professionals, Sika makes its products available through a broad network of distributors. Be it in professional trade or in retail channels, regarding product quality, Sika does not differentiate between the two market segments. Packaging and appearance of Sika products have been adapted to different requirements of the retail business. We believe that every customer deserves the best product.

For those who are designing and engineering the fresh and hardened concrete specifications, Sika provides expert support, from the drawing board to the job site. We welcome the chance to work with specifiers and help design cast-in-place concrete to exceed your expectations – whether it is a high-strength mix or a unique color or finish texture you want to specify. In addition to our support services and concrete admixtures, we have a comprehensive range of proven products from “basement to roof” for your project.

Learn more about our full range of construction solutions available.

Sika’s Cement Additives Technologies

Each individual cement plant has different characteristics of local raw materials, availability of possible clinker replacements (such as supplementary cementitious materials - SCM) and varying conditions during the cement grinding process.

In addition, local standards and customers’ needs regarding cement performance vary due to unique climate and construction methods. Therefore, the solution for highest possible production rates or maximized use of supplementary cementitious materials needs to be adjusted individually.

Sika offers many types of cement additives known to improve cement quality, increase production efficiency and meet your local demands:

Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, e.g. powder flowability.

There are several ways to increase the mechanical strength of cement. It is common to use cement additives that increase the mechanical strength by chemical activation, without changing the cement surface and particle size distribution. Alkanolamines are frequently used and are able to increase the compressive strength (at different or all age) by max. five MPa.

Clinker is often replaced with supplementary cementitious materials (SCM) such as granulated blast furnace slag, natural pozzolanes and fly ash in order to reduce CO2 emissions and material cost. However, SCM may counteract strength development, powder flowability, mortar workability and durability, which are critical for cement quality.